Page 72 - Port Douglas Magazine 35

P. 72

THE BIG CRUSH:

Sugar Production the sweet stuff

Sugar production is a key element to making Port Douglas the

sweetest of tourist destinations.

Whatever time of year a visitor arrives, they will see sugar cane

paddocks in a stage of their 12-18 month production cycle. Canes

in flower or standing tall as they near harvest are as central to the

local landscape as the views to the horizon over the Coral Sea and

along the mountain range to the lush, tropical Daintree Rainforest.

Sugar is sourced from beet, in cold climates, and canes in the tropics.

While sugar cane was aboard the First Fleet to Australia in 1788, its

production did not succeed until it was planted much further north.

By the mid 1860s, commercial production was established. But it

was hard graft with cane cutters harvesting the crop by hand in often

dangerous conditions and, almost always, searing heat and sunshine.

It was 1960s before mechanised cane cutting became widespread.

Today in the region, about 20 varieties of cane are grown and their

life cycle sees them grow from seedlings to heights up to 7 metres

over a 12 to 18 month period. A crop takes a full year to mature.

“It was hard graft with cane cutters harvesting the crop

by hand in often dangerous conditions and, almost

always, searing heat and sunshine.”

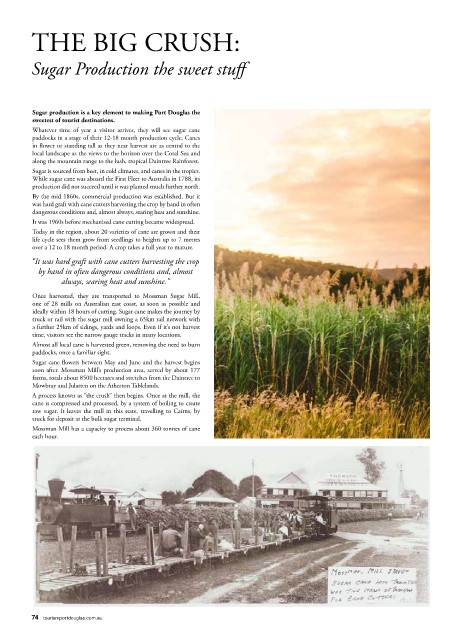

Once harvested, they are transported to Mossman Sugar Mill,

one of 28 mills on Australian east coast, as soon as possible and

ideally within 18 hours of cutting. Sugar cane makes the journey by

truck or rail with the sugar mill owning a 65km rail network with

a further 25km of sidings, yards and loops. Even if it’s not harvest

time, visitors see the narrow gauge tracks in many locations.

Almost all local cane is harvested green, removing the need to burn

paddocks, once a familiar sight.

Sugar cane flowers between May and June and the harvest begins

soon after. Mossman Mill’s production area, served by about 177

farms, totals about 8500 hectares and stretches from the Daintree to

Mowbray and Julatten on the Atherton Tablelands.

A process known as “the crush” then begins. Once at the mill, the

cane is compressed and processed, by a system of boiling to create

raw sugar. It leaves the mill in this state, travelling to Cairns, by

truck for deposit at the bulk sugar terminal.

Mossman Mill has a capacity to process about 360 tonnes of cane

each hour.

74 tourismportdouglas.com.au