Page 17 - Port Douglas Magazine 33

P. 17

‘Eureka!’ innovations came every few years that would AND THE FUTURE

revolutionise how cane was harvested, something In recent times sugar has had a bit of a public relations

bigger and faster would emerge, designs went from problem, and with a war on the white granular

strength to strength. Knives were replaced by T-Rex- as health villain number one to the “I quit sugar”

sized ride on lawnmowers. Colossal harvesters flattened

fields in a fraction of the time, chewing up and spitting revolution it’s little wonder that the future of the sugar

out 100 tonnes of cane per hour. industry might look a bit bitter.

That’s what you would think, but the little town

As harvesters bustle row by row, the need for quick continues to keep its sugar industry a world leader,

transport to the mill was mirrored - a network of since all of the sugar from the Mossman Mill is

narrow-gauge tracks would be the answer. Crisscrossing exported overseas and sold on the NY11 stock

throughout the countryside, they carried charming

little cane trains that chug a lug a tether of metallic exchange. To date there has been no impact from any

mesh bins popping in and out of the quilting paddocks the anti-sugar movement.

even passing through the main street of Mossman to The profit line of Queensland growers hinges on

speedily bring chopped cane to be crushed. countries such as Brazil, Thailand, and potentially

The small locomotives, initially run by steam but later India. It is their annual sugar production and how

much cane they divert between sugar and ethanol

streamlined to diesel, still remain an important part of

the cane crushing season with hundreds of kilometres that drives the world sugar price. If they produce

of tracks laid. However roadways are becoming just large quantities of sugar forcing the world supply into

a surplus the price drops and if they don’t produce

as efficient, and you now see more huge cane trucks enough and the world supply goes into deficit the price

busily ferrying the cut product to the mill. increases.

These cane railways will continue to be an efficient way When Far Northern Milling purchased the Mossman

of transporting the crop as well as delighting the many

visitors to the areas. I can’t think of anyone who doesn’t Mill, securing for the future was top priority. They are

keenly aware that neither the mill nor the growers will

love these simple railways.

survive long-term relying on the exports of the raw

sugar market. Diversification and value-adding to the

CRUSH HOUR mill products such as cane and molasses are critical for

the survival of the industry.

When it comes to crushing the Mossman Mill has Daintree Bio Precinct Ltd, which is the parent

some serious chops to produce on a large scale. From company of Far Northern Milling, has completed an

its early stages it punched well above its weight, and 18-month ‘options assessment’ process looking for

remains a central and pivotal part of the agricultural value-adding opportunities for the Mossman Mill. The

climate of the region.

‘CocoNutZ’ project, which involves the production of

The hub of the community is the Mossman Central Kecap Manis, an aromatic sweetened soy sauce, was

Mill, hotels and town amenities popping up around recently announced. It may have the potential to

the crushing headquarters. It started life as a grower- underpin the future of the Mossman Mill. They are

owned co-operative sugar mill back in 1894. Mrs also currently working on an AD & Biogas solution

Annie Rose had the distinct honours of feeding the to utilise the waste streams from the mill to produce

first sugarcane into the mill in 1897, with the mill steam and electricity.

producing its first sugar after crushing 27,905 tonnes

of cane for the initial season.

Leading the industry in 1906, the Mossman Mill AND THEY WERE ALL

became the first Queensland mill to crush over YELLOW TOO

100,000 tonnes of cane. That season lasted just under

eight months, extending from June 1906 to late Another indirect allure of cane growing that gives a

January 1907. giddy feeling are the fields of sunflowers. These lively

Another first was achieved when General Manager blooms put smiles on the faces of visitors and locals

as well as likes on Insta feeds. Grown not purely

Louis John Frederick Prince pioneered the use of for aesthetic, but rather they serve an important

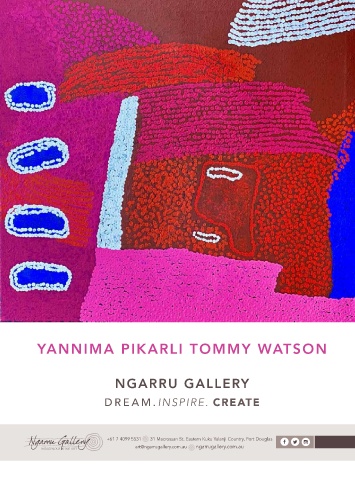

computers for cane payment accounting and, in 1971, agricultural purpose. YANNIMA PIKARLI TOMMY WATSON

a big deal at the time when Mossman purchased the

first process control computer used in the world sugar Sunflowers are a vibrant rotational crop, used in

industry. the unplanted paddocks. Once the cane has been

ploughed out the field is sometimes given a 12-month

“Sugar cane deserves Despite sugar’s tumultuous and challenging times, over rest to replace nitrogen back into the soil, after which

the years the Mossman Sugar Cane Mill holds firm in

to be celebrated. The the face of adversity, managing to increase their hourly time the sunflowers are ploughed back, and in goes NGARRU GALLERY

the cane to be harvested and crushed for another year.

crushing capacity from 25 tonnes to a whopping 350.

robust crop has been Today the mill crushes 500,000 tonnes of cane, Sugar cane deserves to be celebrated. The robust DREAM. INSPIRE. CREATE

crop has been fuelling the lives of Mossmainians

fuelling the lives of producing over 65,000 tonnes of raw sugar from more for centuries. It has kick-started a culture and a

than 120 farms supporting the local community.

community, so when you have your next cuppa ask for

Mossmainians for The Mossman Mill is the second largest employer two sugars and take comfort in the sweet spot.

in the Douglas Shire after the Shire Council. There

centuries.” are 150 direct mill employees during the season and +61 7 4099 5531 31 Macrossan St. Eastern Kuku Yalanji Country, Port Douglas

around 80 in the off-season. It supports around 550

indirect jobs that include cane harvesting contractors,

truck drivers, farmhands, and the like. [email protected] ngarrugallery.com.au

PORT DOUGLAS MAGAZINE 17